Rotator Soldandi CR-350 cum rotis PU/Chalybeis ad fabricationem vasorum

✧ Introductio

Rotator ad soldaduram conventionalis 350 tonnarum est instrumentum robustum destinatum ad rotationem moderatam et positionem materiarum gravissimarum, praesertim earum quae usque ad 350 tonnas metricas (350,000 kg) ponderant, facilitandam. Hoc genus rotatoris essentiale est in industriis quae fabricationem et soldaduram magnarum partium requirunt, ut navium constructione, oleo et gasio, et machinarum gravium fabricatione.

Proprietates et Facultates Claves

Capacitas Oneris:

Pondus maximum materiae fabricandae 350 tonnarum metricarum (350 000 kg) sustinet, quo fit ut ad usus industriales amplissimos aptus sit.

Mechanismus Rotationis Conventionalis:

Systema rotatorium vel cylindrorum robustum habet, quod rotationem lenem et moderatam materiae laborandae permittit.

Typice motoribus electricis magni momenti vel systematibus hydraulicis ad fidam functionem impelluntur.

Praecisa Celeritatis et Positionis Imperium:

Instructus systematibus moderandi provectis ad accuratam adaptationem celeritatis rotationis et positionis.

Impulsores celeritatis variabilis operatoribus permittunt celeritatem rotationis ad specificum opus soldadurae accommodare.

Stabilitas et Rigiditas:

Constructa cum robusta structura ad onera et contentiones significantes cum tractatione operum 350 tonnarum coniunctas sustinendas destinata.

Partes roboratae stabilitatem in operatione praestant, vibrationem et motum minuentes.

Proprietates Salutis Integratae:

Inter mechanismi securitatis sunt puga sistendi in casu necessitatis, praesidium contra nimium onus, et interclusiones securitatis ad salutem operationis augendam et accidentia prohibenda.

Ad securum ambitum laboris operatoribus praestandum designatum.

Integratio Perfecta cum Instrumentis Soldandi:

Compatibilis cum variis machinis soldadurae, inter quas MIG, TIG, et soldadurae arcus submersi, quod fluxum laboris expeditum per operationes soldadurae faciliorem reddit.

Applicationes Versatiles:

Idoneus ad amplam applicationum varietatem, inter quas:

Constructio et reparatio navium

Fabricatio vasorum magnorum pressorum

Congeries machinarum gravium

Fabricatio ferri structuralis

Beneficia

Productivitas Aucta: Facultas rotandi magnas res efficaciter tractationem manualem minuit et totum fluxum operis emendat.

Qualitas Suturae Auctior: Rotatio moderata et positio accurata ad suturas altae qualitatis et meliorem integritatem iuncturae conferunt.

Sumptus Laboris Reducti: Automatio processus rotationis necessitatem laboris additi ad minimum redigit, ita sumptus productionis totales imminuens.

Machina rotatoria ad suturam conventionalem trecentas quinquaginta tonnas capacitatis necessaria est industriis quae partes ingentes tuto et efficaciter tractare et suturare debent, ut qualitatem optimam in operationibus fabricationis praestent. Si quaestiones specificas habes vel plura de hoc instrumento scire vis, libenter roga!

✧ Specificatio Primaria

| Modellum | Cylindrus Soldandi CR-350 |

| Capacitas Vertendi | Maximum 350 tonnarum |

| Capacitas Oneris Impulsoris | Maximum 175 tonnarum |

| Capacitas Oneris Otiosi | Maximum 175 tonnarum |

| Modum Adapta | Adaptatio clavi |

| Potentia Motoris | 2*6kw |

| Diameter Vasis | 800~5000mm / Ut petitio est |

| Celeritas Rotationis | 100-1000mm/minOstentatio digitalis |

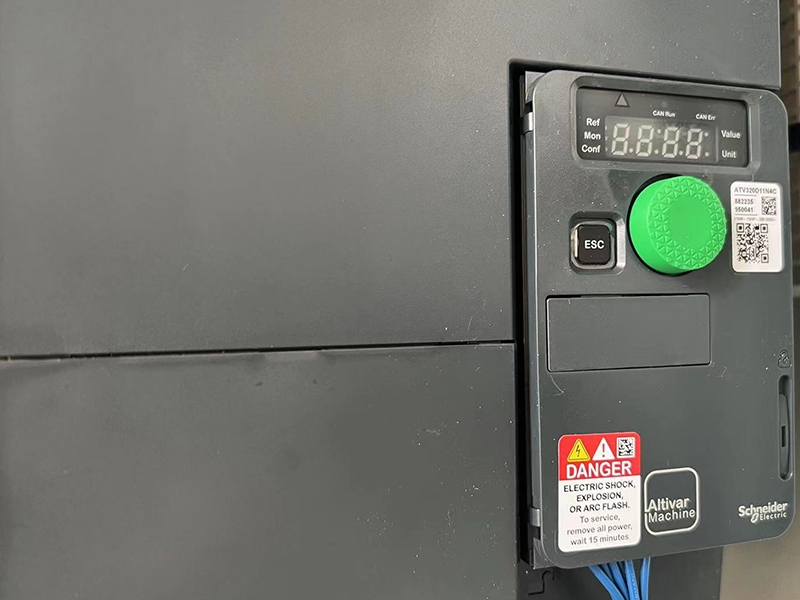

| Imperium celeritatis | Impulsor frequentiae variabilis |

| Rotae volubiles | Chalybs / PU omnes praesto |

| Systema moderationis | Arca moderationis manualis remotae et pedalis pedalis interruptor |

| Color | RAL3003 RUBRUM & 9005 NIGER / Adaptum ad necessitates |

| Optiones | Capacitas magni diametri |

| Basis rotarum mobilium motorizatarum | |

| Arca moderationis manualis sine filo |

✧ Nota Partium Substitutarum

In negotiis internationalibus, omnibus claris notis partium substituendarum utimur ut rotatores soldandi diuturnam vitam praebeamus. Etiam si partes substituendae post annos fractae sunt, usor finalis eas facile in foro locali substituere potest.

1. Variator frequentiae variabilis a Schneider/Danfoss fabricatus.

2. Motores Invertek / ABB cum plena approbatione CE.

3. Arca moderationis manualis remotae vel arca moderationis manualis sine filis.

✧ Systema Moderationis

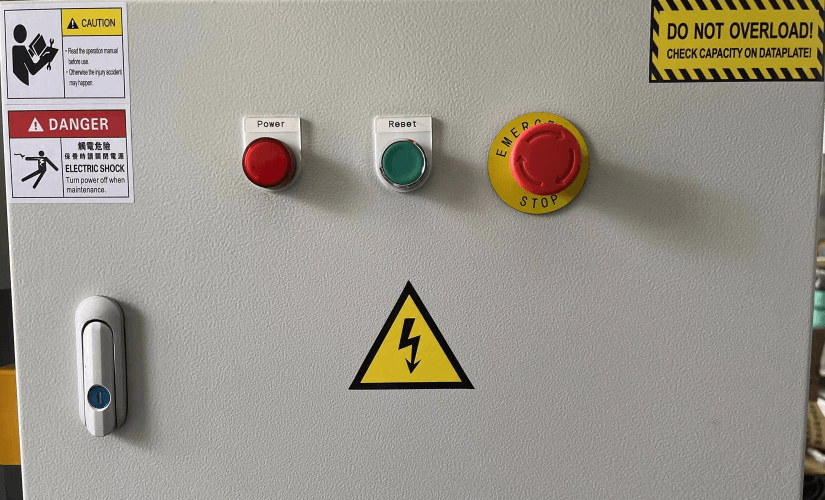

1. Arca moderationis manualis cum ostensione celeritatis rotationis, functionibus antrorsum, retrorsum, luminis potentiae et sistendi in casu necessitatis.

2. Armarium electricum principale cum interruptore potentiae, luminibus potentiae, alarmis, functionibus repositionis et functionibus sistendi in casu necessitatis.

3. Pedal pedale ad directionem rotationis moderandam.

4. Arca moderationis manualis sine filo praesto est si opus est.

✧ Progressus Productionis

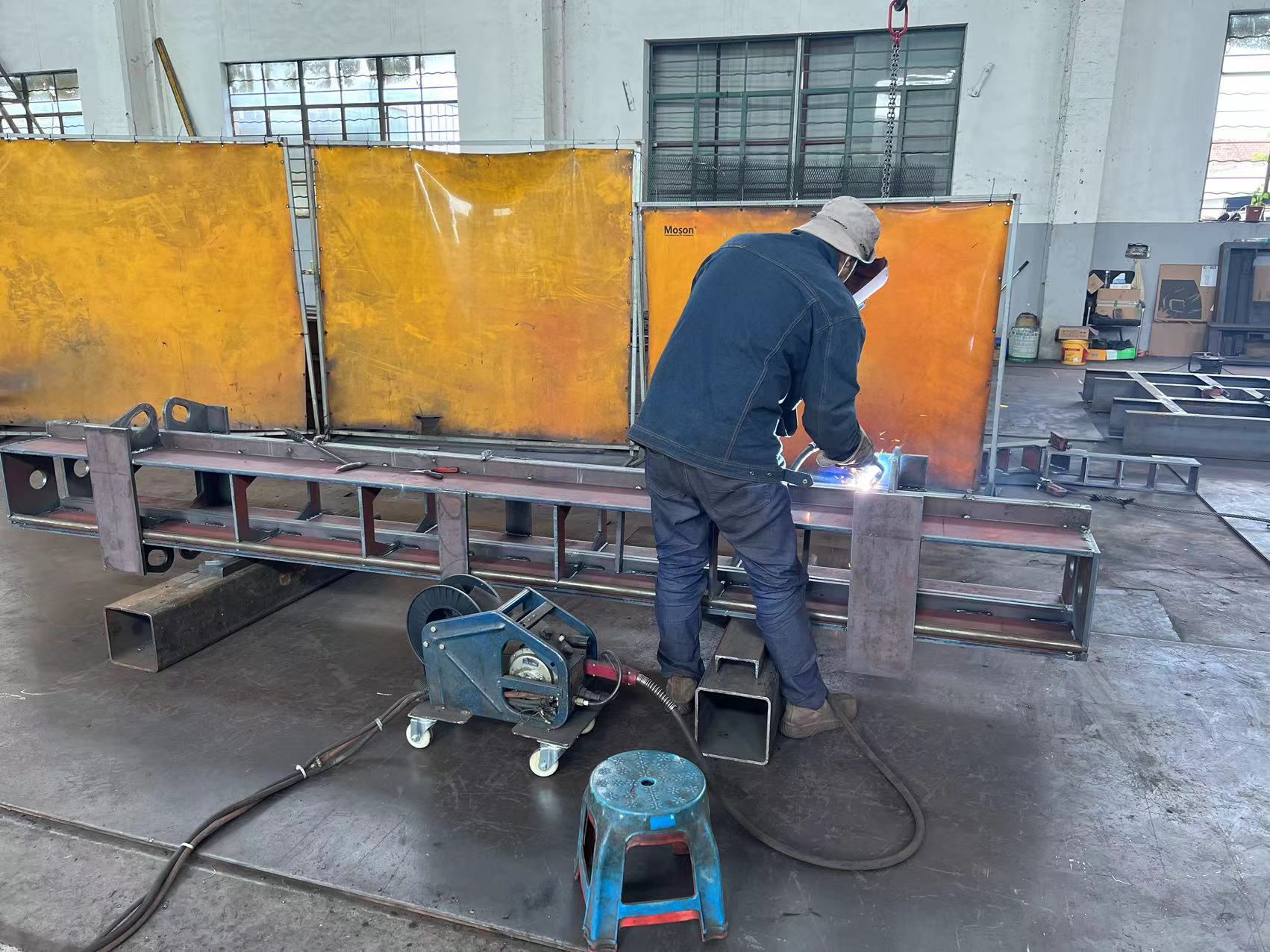

WELDSUCCESS, tamquam opifices, rotatores ad soldandum ex laminis ferreis originalibus producimus, secando, soldando, tractando mechanice, foramina terebrando, componendo, picturando et probando finaliter.

Hoc modo, totum processum productionis sub systemate nostro qualitatis ISO 9001:2015 moderabimur. Et curabimus ut clientes nostri producta altae qualitatis accipiant.

✧ Proiecta Priora